Electric Vehicles are the future. The transition away from the Internal Combustion Engine will change the face of the Commodities industry, creating new sources of demand for certain key metals.

Elementum Metals: 30/11/2020

In 2019, Electric Vehicles (EVs) accounted for just 0.5% of the world’s vehicles, however by 2025, it's expected that 7% of all passenger vehicles will be electric, rising to 38% by 2040. By 2050, most automobile manufacturers are expected to have gone electric,1 as governments encourage users to switch away from both the Internal Combustion Engine and hybrid vehicles. The UK government has gone further by announcing a complete ban on ICEs and hybrid cars after 2035.

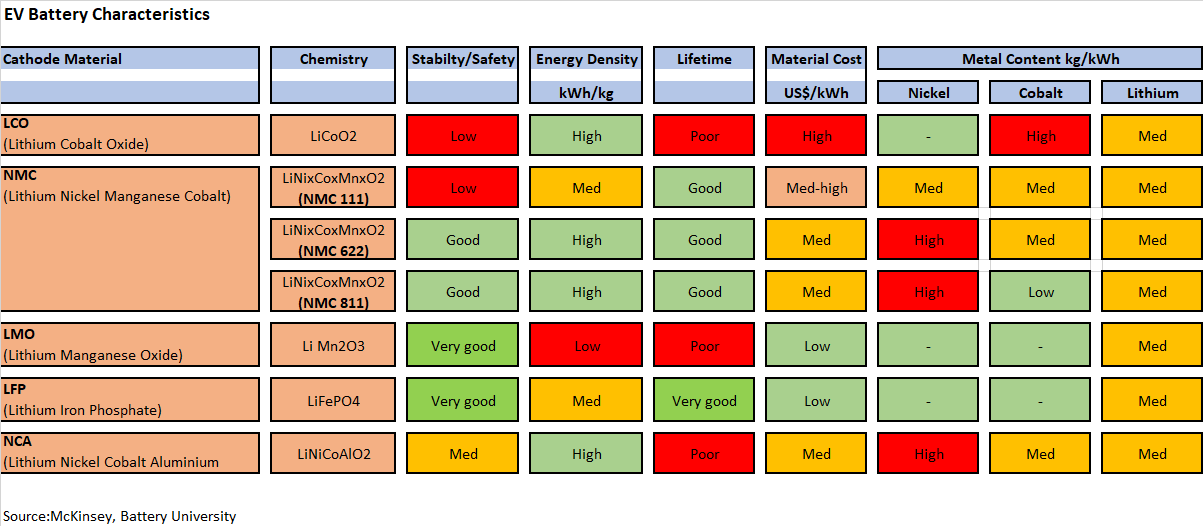

In common with internal combustion vehicles, EV manufacture uses small quantities of gold and silver quantities in electronic circuit boards. However, EVs use far greater quantities of copper and nickel, as well as metals such as lithium, cobalt and manganese.

Electric cars use twice as much copper as those powered by ICEs while larger vehicles’ copper use is even more intensive. Around 22kg of copper is used in an ICE-powered car, 80kg in a battery electric vehicle and 250kg in a battery electric bus.2

Demands for greater vehicle range as well as environmental considerations are bringing about greater nickel use, replacing cobalt and lithium. Battery cathodes with 60% nickel are being replaced by 80% nickel content in order to achieve greater energy density,3 also reducing use of cobalt primarily sourced from the Democratic Republic of Congo. Tesla cars’ nickel-cobalt-manganese or nickel-cobalt-aluminium batteries typically account for 30kg of nickel used in the manufacture of a Model 3.4

Higher quality nickelsulfate has to be used in batteries; this however limits supply as nickelsulfate only accounts for half of total nickel production.5 Elon Musk has been widely reported beseeching the mining community to ‘mine more nickel’ in the face of a supply crunch as nickel consumption is expected to increase by more than 50% by 2050.6

We recently recorded a webinar titled 'Perspectives on Uranium Demand and Supply'. You can view it here. Please use passcode ?3gDUblB